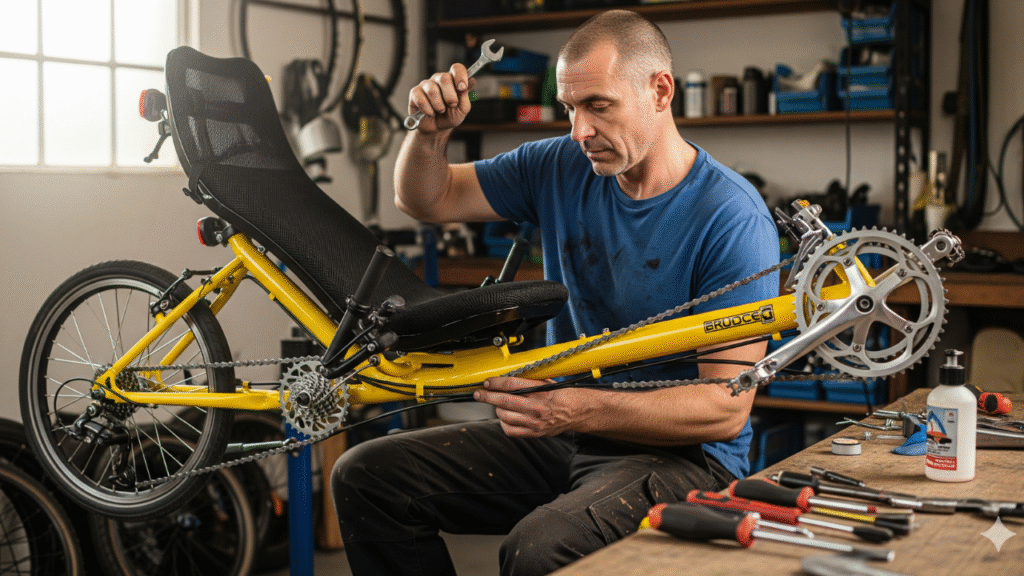

Why Recumbent Bikes Require Special Attention During Repairs

Recumbent bikes are great for comfort and low-impact workouts, but their design brings unique repair challenges. If you want your recumbent bike to last long and run smoothly, these special points matter.

Unique Seating Positions Need Precise Adjustments

Recumbent bikes put riders in a semi-reclined position, which means the seat, backrest, and foot placement must be adjusted precisely. A seat that’s off just a bit can lead to discomfort or strain in knees, hips, or back. During repair, technicians must ensure that all adjustments match the user’s body size and riding style to avoid misalignment or uneven wear.

Special Seat Rails and Sliders Must Be Kept Aligned

Many recumbent bikes have sliding seat rails or rails that let the rider move back and forth. These parts must be smooth and aligned. If the rails are bent, dusty, or rusted, the seat may slide unevenly or get stuck. Repair work must include cleaning, lubrication, and checking that rails are straight and free of obstructions.

Low Frames Can Trap Dust and Moisture

Because of their lower frame height and reclined structure, recumbent bikes often sit closer to the ground. Dust, moisture, and debris can collect under and around the frame, which may lead to corrosion, worn components, or rusted bolts. During servicing, a technician needs to inspect these areas carefully, clean them out, and protect them against moisture.

Different Resistance Mechanisms Require Expert Handling

Recumbent bikes may use magnetic resistance, fan resistance, friction pads, or even more complex systems. Repairs involving resistance components need skill and the right parts. For example, magnetic resistance units are delicate, and friction pads need proper alignment. Mishandling these mechanisms can lead to poor performance, loud noise, or even damage.

Longer Seat Support Means More Stress on Frame Joints

The seat of a recumbent bike is typically supported over a longer span compared to upright bikes. That means more leverage and more stress on joints, bolts, and connection points. Over time, frame joints can loosen or become stressed. In repair work, it’s important to inspect all connection points, tighten bolts, and reinforce or replace worn joints so the frame stays stable and safe.

Pedal Linkage & Crank Arms Are Under Unusual Angles

The way you position your legs on a recumbent bike—usually more stretched out and aligned differently than on traditional upright bikes—puts unique stress on the pedal linkage and crank arms. These parts may wear unevenly or get misaligned faster. Repair work has to consider these angles carefully, ensuring that everything moves freely and doesn’t bind under load. If a crank arm is bent or the linkage is loose, it can affect your comfort and potentially cause injury.

Lubrication Points Are Harder to Reach

Because many recumbent bikes have a low frame profile and parts tucked beneath seats or rails, lubricating moving parts like bearings, linkages, and sliding rails can be more challenging. These parts might not be visible or easily accessible. Missing lubrication in these spots can lead to squeaks, stiffer movement, or premature wear. A technician needs to know where to look—and sometimes remove or loosen parts—to reach hidden lubrication points.

Electronic Components Often Hidden or Protected Differently

In recumbent bikes, consoles, sensors, and wiring are often built into the frame or placed in protected but less accessible spots. This design helps shield them from sweat, dust, and external damage, but it also means that when something goes wrong—say, with the speed sensor or display wires—repairs can be more involved. Wires may run inside frame tubes or under the seat rails. Technicians must be careful when opening or routing them to avoid damaging other parts.

Weight Distribution Puts Extra Load on Bearings

Because of the recumbent’s reclined seating and different beam structure, more weight is often supported by the rear of the bike, by sliding rails, and by certain bearings more than in upright models. That means bearings (in pedal assemblies, seat sliders, etc.) often endure non-standard loads. Wear in these bearings can lead to wobble, noise, or rough motion. Proper repair includes inspecting bearings for play, replacing them timely, and choosing quality bearings meant for those stresses.

Warranty Terms May Require Professional Inspection

Recumbent bike warranties often have specific terms regarding how the bike must be treated, maintained, and repaired. Some warranties are voided if the bike is opened up improperly, or if repairs are done by non-authorized professionals. Because recumbent bikes have design complexities (unusual frame joints, hidden wiring, special slide rails), doing a repair incorrectly may damage parts or compromise safety. A professional inspection ensures the job is done right and keeps warranty protection intact.

Suggested Article: Why Home Gyms Also Need Regular Equipment Servicing

Conclusion

Recumbent bikes offer comfort and joint-friendly workouts, but their design brings special repair needs: accurate seat alignment, well-maintained rails, protection from dust and moisture, correct handling of resistance systems, and strong, stable frame joints. Giving attention to these areas during servicing helps your bike stay reliable, comfortable, and safe.For dependable and expert repair of recumbent bikes (and other gym equipment), you can visit https://treadmillrepairbhubaneswar.in/

3 Comments